gauge galvanized wire

Latest articles

gauge galvanized wire

...

gauge galvanized wire 【gauge galvanized wire】

Read More

gauge galvanized wire1. Zinc pot operators must stick to their posts

...

gauge galvanized wire 【gauge galvanized wire】

Read Moregauge galvanized wire

...

gauge galvanized wire 【gauge galvanized wire】

Read Moregauge galvanized wire

...

gauge galvanized wire 【gauge galvanized wire】

Read Moregauge galvanized wire

...

gauge galvanized wire 【gauge galvanized wire】

Read Moregauge galvanized wire

...

gauge galvanized wire 【gauge galvanized wire】

Read More

gauge galvanized wire

Post time: 23-06-22...

gauge galvanized wire 【gauge galvanized wire】

Read Moregauge galvanized wire

...

gauge galvanized wire 【gauge galvanized wire】

Read More1, galvanized wire mesh molding sheet must be packed with flat hard data, to avoid eternal deformation due to poor packaging. It IS VERY IMPORTANT THAT EACH PACKAGE AND ROLL OF RAW SHEET MATERIAL BE MARKED WITH PRODUCT NAME, STANDARD, QUANTITY, TRADEMARK, batch number, MANUFACTURER, DATE of production, STACKING SYMBOL, INSPECTOR CODE AND INSPECTION CERTIFICATE.

gauge galvanized wire...

gauge galvanized wire 【gauge galvanized wire】

Read MoreThere are many kinds of zinc plating solution, which can be divided into plating solution and no plating solution according to its properties. The galvanized liquid has good dispersion and covering property, the coating crystal is smooth and fine, the operation is simple, the application range is wide, and the long-term use is in the production. However, due to the toxic substances contained in the plating solution, the gas escaping from the plating process has great harm to the health of workers, and the waste water must be treated strictly before discharge.

gauge galvanized wire...

gauge galvanized wire 【gauge galvanized wire】

Read More

Popular articles

- Galvanizing can be done by zincate galvanizing or chloride galvanizing. Appropriate additives should be used to obtain a coating that meets the requirements of this standard. Light treatment should be carried out after light plating. The parts that need to be dehydrogenated for passivation should be passivated after dehydrogenation. Before passivation, 1%H2SO4 or 1% hydrochloric acid should be applied for activation for 5~15s. Passivation shall be treated with colored chromate unless otherwise specified in the design drawings.

The use of galvanized anticorrosion treatment is better, the metallurgical connection between galvanized layer and steel, combined with the appearance of steel as a whole, making the coating more durable, more reliable. In the suburbs, the galvanized thickness of hot dip galvanized can adhere to more than 50 years without repair, in the suburbs or near the seaside, galvanized layer can adhere to more than 20 years without repair, is the choice of anti-rust and anti-corrosion. Coating has strong toughness, in the process of transportation or use, can resist extrusion, withstand some damage, hot dip galvanized anticorrosion treatment both save time and effort, and faster than other processing, than dipping, spraying to save much time and effort.

In order to remove the photosynovium and oxide remaining on the surface of galvanized iron wire after drawing or heat treatment, it is necessary to do the surface treatment of galvanized steel wire before plating. The common surface of low carbon steel wire is the light synovium or oxide of animal or vegetable oil; Medium and high carbon steel in addition to contain animal or vegetable oil components.

And high quality data is constrained by production cost and production conditions, so some welding mesh manufacturers do not meet this requirement, natural in this case, there is no way to improve the strength of the product. In addition to the data, there is the production process, even if it is the best data, but the manufacturer does not meet the production process requirements in the welding, it will also form the product under high pressure welding, so this is also a decline in strength, the process conditions of different manufacturers are also very different, so it forms the market above the product has a difference in strength.

Latest articles

-

-

There are many kinds of galvanized solution, which can be divided into cyanide plating solution and cyanide plating solution. Cyanide galvanizing solution has good dispersion and covering ability, coating crystallization is smooth and fine, simple operation, wide application range, has been used in production for a long time. However, because the plating solution contains highly toxic cyanide, the gas escaping in the plating process is harmful to the health of workers, and the waste water must be treated strictly before discharge.

-

-

-

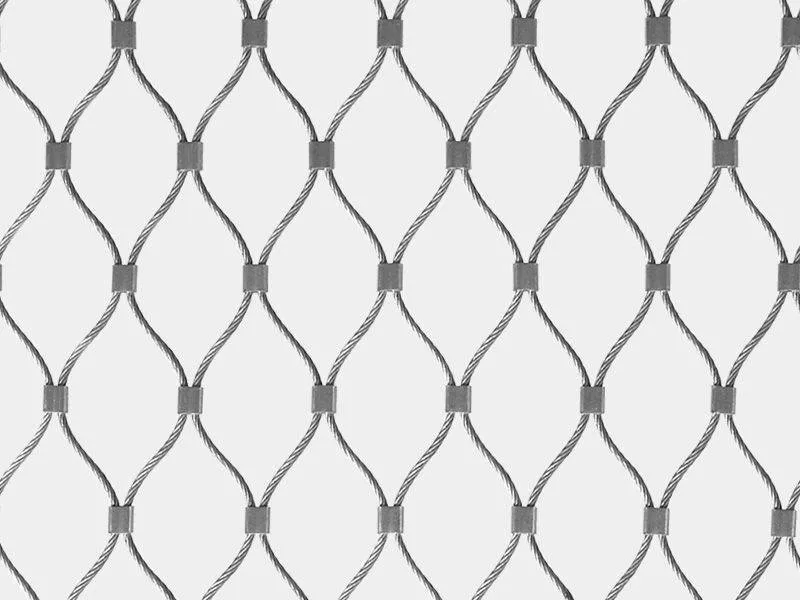

Galvanized hook net price is low: galvanized anti-rust cost is lower than the cost of other paint coating; Galvanized hook mesh durable: galvanized layer and steel is metallurgical combination, become a part of the steel surface, so the durability of the coating is more reliable; Galvanized hook net impact resistance: galvanized layer forms a special metallurgical structure, this structure can withstand mechanical damage in transport and use; Galvanized hook mesh quality is high: every part of the plated parts can be plated with zinc, even in the depression, sharp corners and hidden places can be fully protected.

-

First, comparative selection

Links

Stålristen er en uundgåelig del af mange konstruktions- og infrastrukturprojekter. Uanset om du bygger en gangsti, en trapper, en platform eller endda et gitter til afløb, er stålristen et essentielt element, der sikrer sikkerhed, holdbarhed og funktionalitet.

The applications of banded bar grating are numerous. In industrial settings, it is commonly used for walkways and platforms, providing a safe passage for workers and equipment. In the commercial realm, it is found in shopping centers, parks, and public spaces, contributing to an appealing yet practical environment.

Ο τίτλος αυτού του άρθρου είναι Κάλυμμα αποχέτευσης καναλιού Ένας κρίσιμος παράγοντας για τη διαχείριση υδάτων.

2. Oil and Gas Industry In drilling operations, shaker screens are used to separate drilling fluids from cuttings, which helps maintain efficient drilling performance.

- .

Types of Trench Drain Grates

3. Storlek och form Mät det område där golvristan ska installationeras för att säkerställa rätt storlek och passform.

Алюмінієва настилка для каткових шляхів міцність та легкість

Zubaté ocelové tyče nacházejí široké uplatnění v různých průmyslových odvětvích. V konstruktivním inženýrství se často používají pro vytváření pevných spojů mezi různými stavebními prvky. Jejich schopnost efektivně uchopit a stabilizovat další komponenty je činí ideálními pro použití v mostech, budovách a dalších infrastrukturálních projektech.

Types of Shaker Screens

La grille métallique expansée est fabriquée à partir de feuilles de métal qui sont coupées et étendues pour créer une structure de maillage. Le terme 4% d'expansion fait référence au rapport entre la surface initiale du métal et sa surface après expansion. Cela signifie que le fil de métal est étiré pour créer des ouvertures qui représentent 4% de sa surface totale. Ces ouvertures permettent un excellent drainage, de la ventilation, ainsi qu'un poids léger tout en conservant une bonne résistance.

Mesh Grating Flooring A Versatile Solution for Various Applications

Yhteenvetona, grating-lattialaatta on erinomainen valinta teollisuuden, liiketoiminnan ja muiden ympäristön tarpeisiin. Sen kestävyys, helppo asennus ja monet käyttömahdollisuudet tekevät siitä houkuttelevan vaihtoehdon asiakkaille, jotka etsivät luotettavaa ja pitkähköä ratkaisu lattioidensa tarpeisiin.

Aluminum bar grating also comes in various design options, including flush top, rectangular bar, plank, and I-bar, allowing for flexibility in meeting different project requirements. These design options offer different load-bearing capacities and aesthetic appearances, providing versatility in usage.

Het ontwerp van gratings vereist een diepgaand begrip van materiaaleigenschappen en golftheorie. Innovaties in nanotechnologie hebben geleid tot de ontwikkeling van nieuwe materialen die de prestaties van gratings kunnen verbeteren. Hierdoor kunnen ingenieurs en wetenschappers hun ontwerpen verder verfijnen om betere en meer efficiënte optische systemen te creëren.

Steel grating flooring is an increasingly popular choice in various industries, thanks to its unique combination of strength, durability, and versatility. Steel grating consists of a series of parallel steel bars, spaced apart and welded together, creating a grid-like structure. This design allows for excellent load-bearing capabilities while providing effective drainage and ventilation.

Conclusion

Steel Grating

Grated metal floors, also known as metal grating or grated floor systems, have emerged as a popular choice for various industries, thanks to their unique combination of strength, durability, and functionality. These flooring solutions are constructed from a range of materials, including steel, aluminum, and fiberglass, and are characterized by their open design that allows for superior drainage and ventilation.

Steel grid walkways have gained significant popularity in various industrial and commercial settings due to their durability, safety, and versatility. These walkways, made from high-quality steel, provide a robust solution for pedestrian access in places that demand both strength and stability. This article explores the advantages of steel grid walkways, making them an ideal choice for numerous applications.

Conclusie

In addition to their functional advantages, galvanised grids contribute to sustainability efforts. With the construction industry being a significant contributor to environmental degradation, the shift toward sustainable materials is essential. Galvanised steel can be recycled, allowing for the reduction of waste and promoting a circular economy. This recycling capability aligns with global efforts to minimize the ecological footprint of construction and industrial processes.

Environmental Protection and Sustainability: The use of shale shaker screen mesh contributes to environmental protection by minimizing the disposal of hazardous waste materials. By efficiently removing solid particles from the drilling fluid, the mesh reduces the volume of waste that needs to be disposed of, aligning with regulatory requirements and public expectations for sustainable operations.

L'acciaio inox satinato è noto per la sua durata e resistenza. Grazie alla sua composizione chimica, resiste alla corrosione, ai graffi e all'usura, rendendolo particolarmente adatto per applicazioni dove la robustezza è fondamentale. Inoltre, l'acciaio inox è un materiale igienico, poiché non favorisce la crescita di batteri e altri microrganismi. Questa qualità è particolarmente importante nel settore alimentare e nelle strutture sanitarie, dove l'igiene è una priorità.

Weight is an essential factor to consider during transportation and installation. Heavier gratings may require specialized equipment for moving and positioning, while lighter options could be handled by fewer personnel. Additionally, the weight can impact the overall load-bearing capacity of the structure where the grating is installed. In applications where heavy machinery or foot traffic is expected, it becomes crucial to choose a weight configuration that ensures longevity and stability.

Press-locked Stahlgitter Eine effiziente Lösung für industrielle Anwendungen

Bar Grating Panels An Overview of Their Applications and Advantages

Konklusjonen er klar tykkfarget sveiset stangrist er en utmerket investering for alle som trenger et robust, pålitelig og sikkert alternativ for gratingløsninger, samtidig som de tar hensyn til miljøet.

Stainless steel can be recycled, which is great for sustainability.

En conclusion, le grillage de sol représente une solution à la fois pratique et élégante pour de nombreux espaces. Que ce soit pour un usage industriel, commercial ou résidentiel, il offre à la fois sécurité, fonctionnalité et esthétique. Avec l’évolution des matériaux et des designs, le grillage de sol est devenu non seulement un choix fonctionnel mais aussi un élément clé de l’architecture moderne. Pour ceux qui envisagent d’intégrer ce type de revêtement dans leurs espaces, il est important de considérer les différents aspects afin de faire le meilleur choix possible.